Article PPS300

Poles for Pedestrian Crossings

|

m

|

m

|

mm

|

mm

|

mm × mm

|

mm

|

mm

|

mm

|

Kg

|

m²

|

m × m × m

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| PPS300 | 6,5 | 1 | 211 | 89 | 186 × 45 | 3000 | 4 | 4 | 199 | 5,77 | 1,40 × 1,40 × 1,10 |

-

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard EN 40-5, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

-

Poles for pedestrian crossings are made of S235JR and S355JJR steel (in compliance with UNI EN 10025 standards).

-

The tolerances are compliant with the EN40-2 standard.

-

- UNI EN 1461 – Hot-dip galvanized coatings on finished ferrous products and steel articles.

- UNI EN 10025 – Hot rolled products of structural steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Welding procedure test.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 40 – Lighting columns.

Part 2 – Part 3.

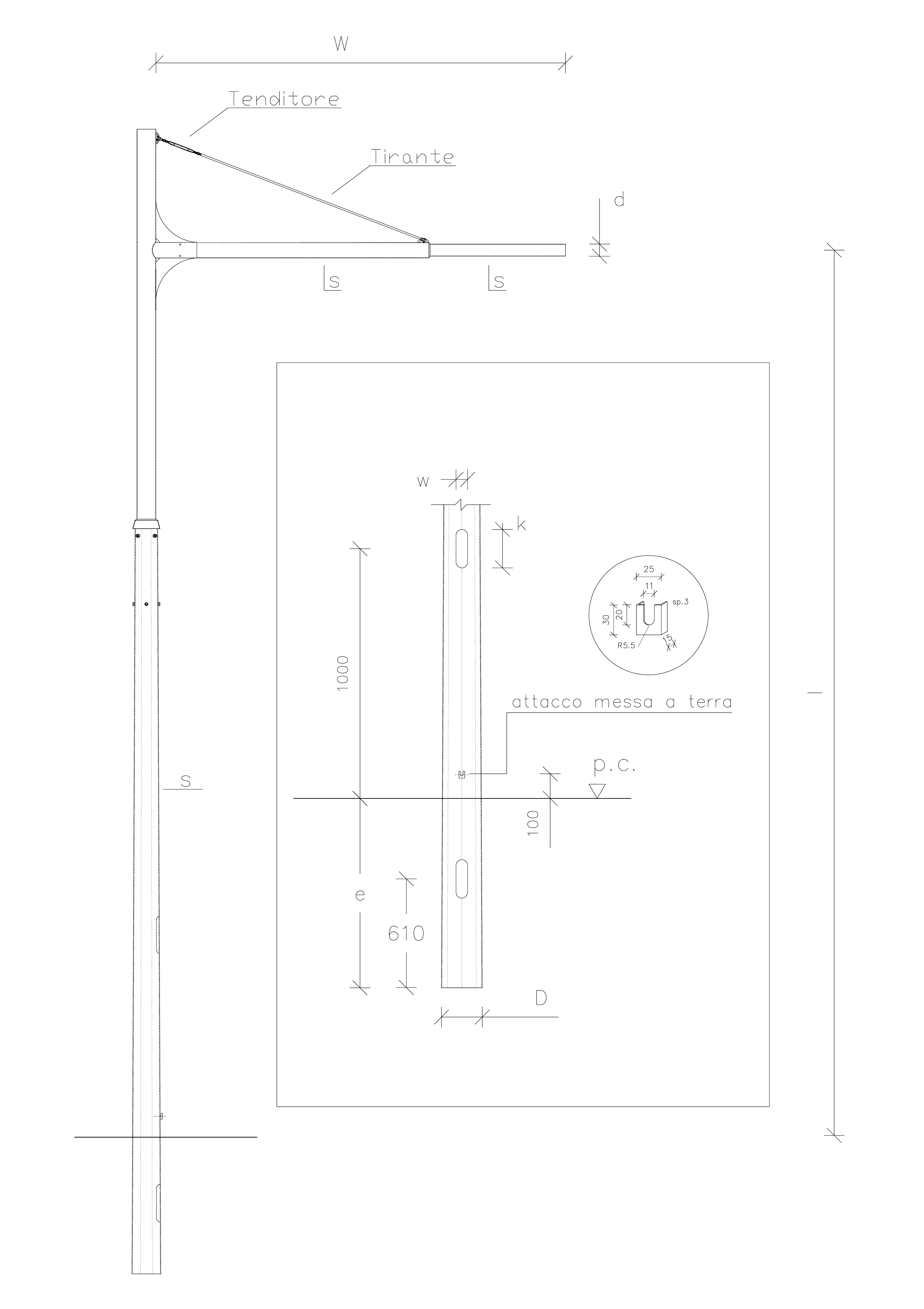

PEDESTRIAN CROSSING POLE model PPS300

The buried pedestrian crossing pole model PPS300, produced by NCM, is composed of two parts: a base with an octagonal section and a tapered circular arm made of multiple elements. The base, consisting of a straight octagonal pole, is manufactured from cold-formed steel sheets by press-bending and longitudinal welding with an automatic welding process. The tapered arm, composed of multiple elements with a circular section, is fixed to the pole by bolts and a self-centering ring. It is equipped with a decorative steel tension rod with a turnbuckle.

The pole comes with the following standard features:

- Hot-dip galvanized coating, immersed in molten zinc in compliance with UNI EN ISO 1461.

- Cable entry hole located 610 mm from the base, with dimensions of 186×45 mm.

- Grounding support welded to the pole for an M10 bolt, positioned 1100 mm from the base.

- Terminal box slot with dimensions of 186×45 mm, positioned 2200 mm from the base.

- 4 cable holes with a diameter of 20 mm, positioned 90° apart and 3100 mm above ground.

Materials:

The traffic light poles are made of S235JR and S355JR steel (in accordance with the UNI EN 10025 standard).

The dimensional tolerances comply with the EN 40-2 standard.

Dimensional characteristics of the pole:

| Maximum arm height above ground | : | mm | 6500 |

| Burying | : | mm | 1000 |

| Octagonal base diameter | : | mm | 211 |

| Base thickness | : | mm | 4 |

| Cylindrical arm diameter | : | mm | 114/89 |

| Arm thickness | : | mm | 4 |

| Arm projection | : | mm | 3000 |

CE Marking:

The poles are “CE” marked by applying an adhesive label (no. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must indicate the following: reference standard EN 40-5, manufacturer’s initials, year of manufacture, product code, and the certification number authorizing CE marking.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.