Article TPVC121

PVC caps for pole top

|

Description

|

mm

|

mm

|

mm

|

|

|---|---|---|---|---|

| TPVC121 | Polyethylene Pole Caps | 121 | 6 | 28,5 |

-

The caps are CE marked.

-

The material of the caps is low-density polyethylene (LDPE).

-

Dimensional tolerances for these low-density polyethylene (LDPE) caps are ±0.1 mm for sizes up to 100 mm and ±0.2% for sizes above. Angular tolerances are ±0.5°.

-

- ISO 1133 – Plastics: Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics.

- ASTM D1505: Standard Test Method for Density of Plastics by the Density-Gradient Technique.

- ISO 527/1A – Plastics: Determination of tensile properties – Part 1: General principles.

- ISO 180/A – Plastics: Determination of Izod impact strength.

- ISO 868 – Plastics and ebonite: Determination of indentation hardness by means of a durometer (Shore hardness).

- ISO 75-2 – Plastics: Determination of temperature of deflection under load – Part 2: Plastics and ebonite.

- ISO 306 – Plastics:Thermoplastic materials – Determination of Vicat softening temperature (VST).

- DIN 53765: Determination of melting point using Differential Scanning Calorimetry (DSC).

- ISO 9001: Quality management systems – Requirements.

CLOSURE CAPS IN PVC model TPVC121

The polyethylene caps, model TPVC121, produced by NCM, are specifically designed to seal the upper end of light poles. Featuring high mechanical strength, they provide long-lasting protection against exposure to weather elements. These caps are ideal for preventing the entry of water and debris, ensuring the longevity and efficiency of the light poles.

Thanks to their sturdiness, they help maintain a neat appearance and reduce the need for maintenance. They represent a practical and effective solution to protect the ends of poles and preserve their integrity over time.

TYPICAL PROPERTY VALUES:

| PROPERTY | TYPICAL VALUES | UNIT | TEST METHODS |

|---|---|---|---|

| Melt Flow Rate | at 190 °C and 2.16 kg | 7.5 | dg/min |

| at 190 °C and 5 kg | 28 | dg/min | |

| Melt Volume Flow Rate (MVR) | at 190 °C and 2.16 kg | 10 | ml/10 min |

| at 190 °C and 5 kg | 33 | ml/10 min | |

| Density | 920 | kg/m³ | ASTM D1505 |

| MECHANICAL PROPERTIES | |||

| Tensile Test | Break Strength | 10 | MPa |

| Tensile Modulus | 130 | MPa | |

| Elongation at Break | 120 | % | |

| Yield Strength | 8 | MPa | |

| Notched Izod Impact | at 23 °C | 45 | kJ/m² |

| at -30 °C | 9 | kJ/m² | |

| Shore D Hardness | 40 | – | ISO 868 |

| THERMAL PROPERTIES | |||

| Heat Deflection Temperature | at 0.45 MPa (HDT/B) | 43 | °C |

| Vicat Softening Temperature | at 10 N (VST/A) | 89 | °C |

| DSC Test | Melting Point | 107 | °C |

| Enthalpy Change | 125 | J/g |

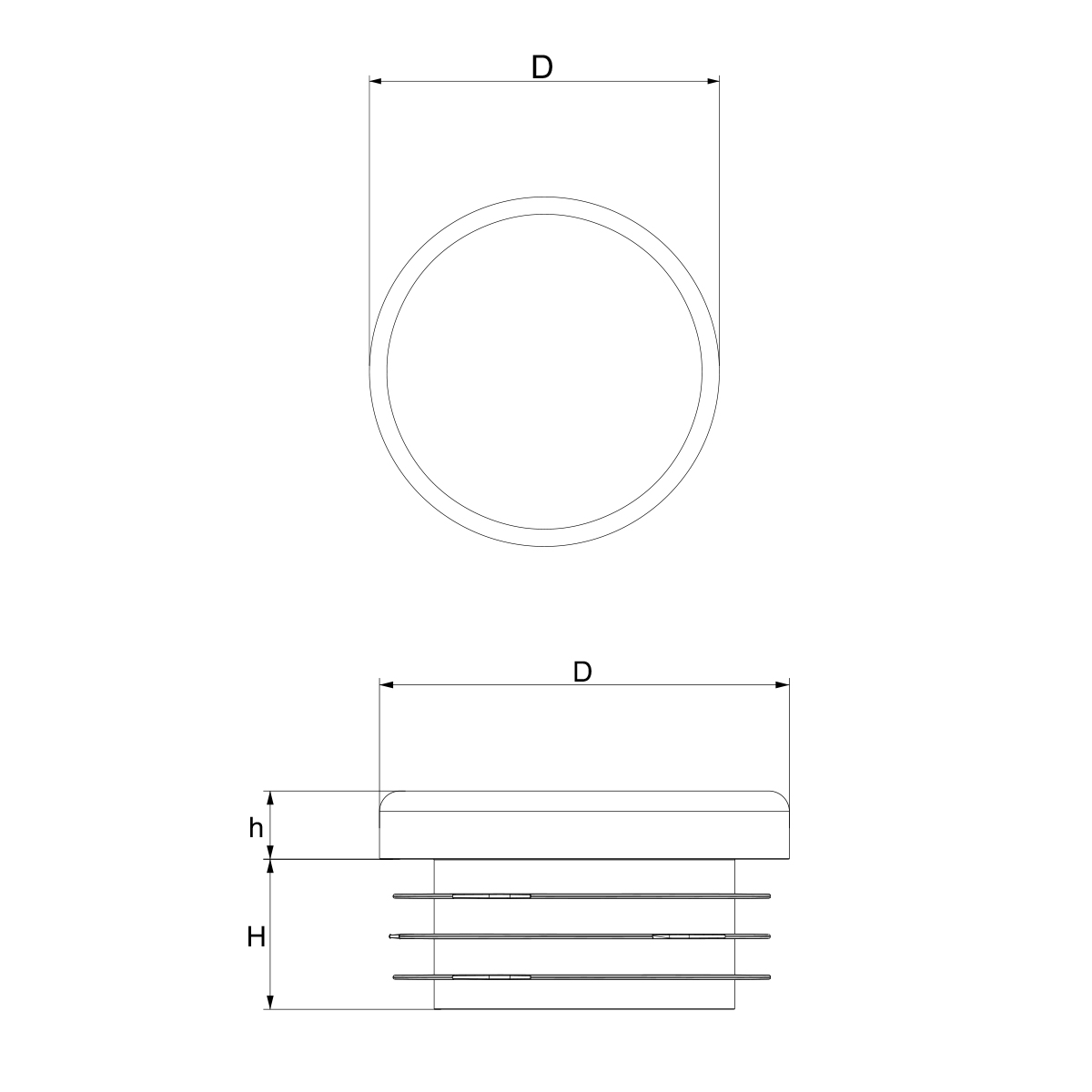

Dimensional Characteristics of PVC Closure Caps:

| Diameter | : | mm | 121 |

| Head height | : | mm | 6 |

| Body height | : | mm | 28,5 |