Article TM250P

Motorized mobile crown towers MEGAFAR

MOTORIZED MOBILE CROWN HIGH MAST MEGAFAR

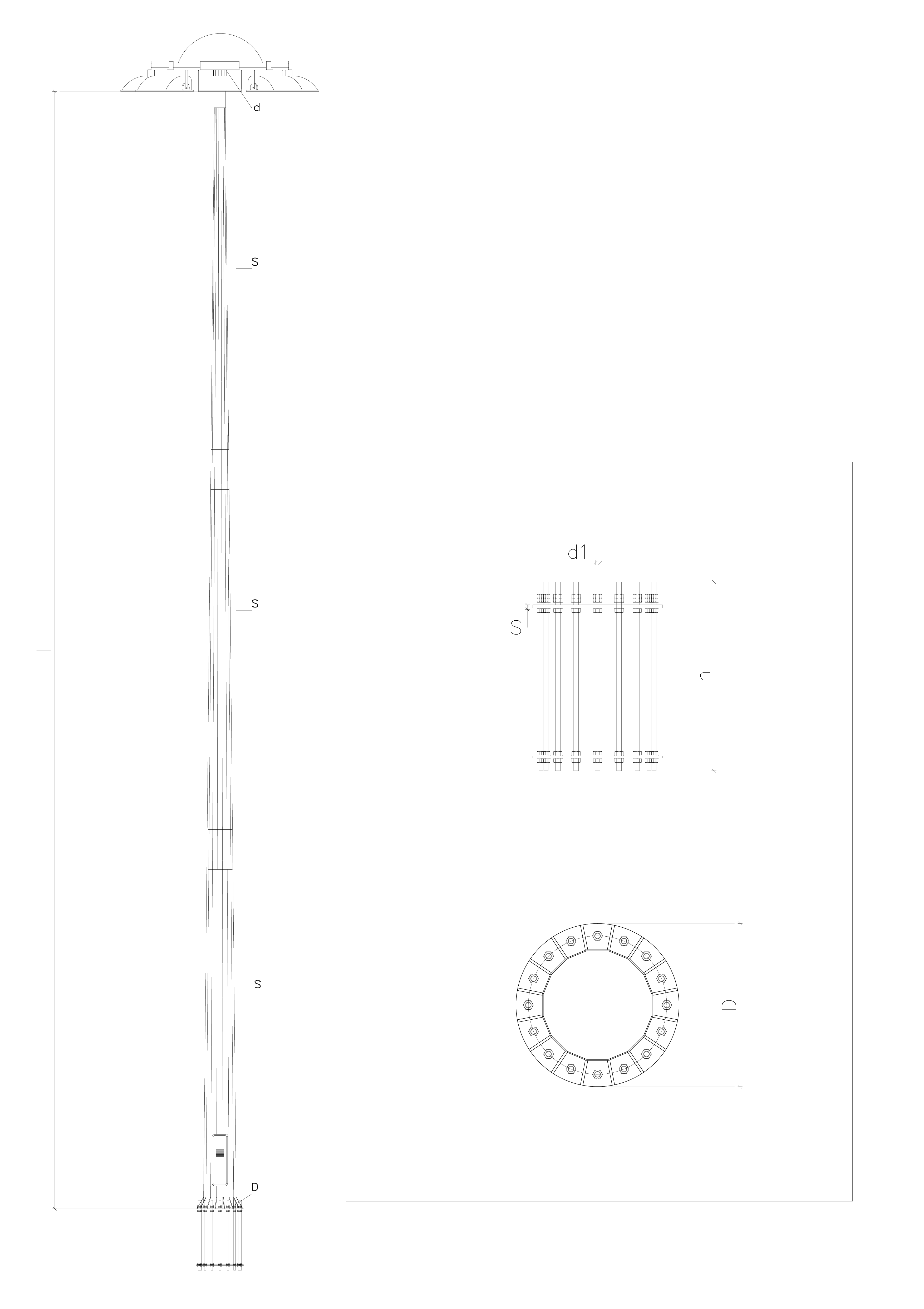

The motorized mobile crown high mast features a truncated-conical shape with a polygonal cross-section, made from cold-pressed steel sheets with longitudinal welding. The welding process complies with the UNI EN ISO 15614-1 standard.

Structure:

- Mast: The mast is composed of three sections joined on-site using a self-locking slip-on-joint system.

- Base section: It houses the lifting winch, accessible through a door equipped with an anti-vandalism lock. The base section is equipped with a suitably ribbed plate for connection to the foundation plinth by means of anchor bolts and is provided with an earthing system.

Motorized Mobile System:

- Pole head: Located at the top of the mast, it houses the pulley for the rope, the projector-crown hooking system, anti-rotation centering pins, and the electrical socket body, ensuring the internal power cables remain fixed.

- Mobile crown: Made of steel, this circular crown supports the lighting fixtures and related electrical equipment and is attached to the trolley.

- Trolley: Constructed from steel, it moves along a guide fixed to the mast via rollers. The trolley attaches to the pole head using two steel plates that support the crown during operation.

- Guide: Made of lightweight alloy, the guide runs along the mast’s entire length, ensuring smooth trolley movement.

- Parachute brake: This exclusive braking system consists of three stainless steel elements. The system is active during normal operation and ready to engage during lifting or lowering if the rope slackens.

- Traction rope: The high-strength galvanized steel rope is attached to the trolley on one end and to the drum at the base of the mast near the inspection door on the other.

- Drive system: Mounted on the mast with a tilting device to control rope tension, it includes a worm gear reducer combined with a pre-gear train, driven by a removable electric motor.

- Removable motor: Available with power specifications of 0.75/1.5 kW – 3-phase – 50 Hz – 4 poles at 380V, depending on the load to be lifted. It comes with a control panel and a low-voltage portable push-button control with a 5-meter power cable for safe operation during movement. The push-button includes stop, raise, and lower controls. The motor’s power is drawn from the lighting system’s power line.

Electrical Accessories:

- The projector’s power line is fixed inside the mast and can be disconnected using a lockable switch with a fuse. The number of conductors depends on the required lighting control circuits (standard setup includes one). The line runs from the interlocked socket in the winch compartment to the female socket at the top of the mast.

Protective Dome:

- A semi-spherical fiberglass dome coated with a pigmented gelcoat paint in gray is mounted at the top to protect electrical and mechanical components.

Finish:

- The high mast is hot-dip galvanized in accordance with UNI EN ISO 1461 to protect against corrosion. Upon request, powder coating is available, compliant with UNI EN ISO 12944 standards.

|

m

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

kg

|

m²

|

m x m x m

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| TM250P | 25 | 850/25 | 664 | 180 | 4 - 4 - 4 | 16/M24 | 1050 | 1775 | 36 | 3,10 × 3,10 × 1,60 |

-

The structure is manufactured according to the UNI EN 1090 standard in execution class EXC2, in compliance with CE certification.

-

The shaft is made of S355 JR steel, while the structural components are crafted from S235 JR steel, with properties conforming to the UNI EN 10025 standard, all hot-dip galvanized according to UNI EN 1461 standards. The provided bolts are made of A4-70 stainless steel, compliant with the UNI EN ISO 3506 standard.

-

Dimensional tolerances comply with the UNI EN 1090 standard.

-

- UNI EN 1461: Hot-dip galvanized coatings on finished ferrous products and steel articles.

- UNI EN 10025: Hot-rolled products of structural steels.

- UNI EN 3834: Quality requirements for fusion welding of metallic materials.

- UNI EN 1090-2: Execution of steel and aluminium structures. Part 2 – Technical requirements for steel structures.

- D.M. 17/01/2018: Update of Technical Standards for Construction.

- Circular No. 7 of 21/01/2019: Instructions for the application of D.M. 17/01/2018.

- Legislative Decree 81/2008: Consolidated text on occupational health and safety.

MOTORIZED MOBILE HIGH MAST, WITH BASE PLATE model TM250P

1. METAL STRUCTURES

1.1 Object

The works covered by this Technical Specification concern the supply of n__ metal high masts for lighting, with a height of 25 meters above ground, to be installed by direct insertion into the foundation plinth.

The structures will be located ___________

Nominal service life of the work (NTC 2018 Tab. 2.4.I): 50 anni

Usage class (NTC 2018 § 2.4.2): II

Execution class (UNI EN 1090-2): EXC2

1.2 Performance

The Contractor must provide the following services:

- Supply of materials (profiles, sheets…)

- Prefabrication in the workshop

- Storage in the workshop

- Surface protective treatments (hot-dip galvanizing)

- Material inspection documents

- CE marking of structural components

- Transport to the construction site

- Workshop van with equipment for assembly

- Ground assembly of the high mast and assistance with raising using a crane

- Mechanical assembly of projectors and accessories as per the executive project

- Issuance of a verbal statement upon completion of the work

1.3 Description of the Supply

The supply includes the following works:

High Mast Model TM250P produced by N.C.M. Srl with motorized mobile crown, designed for the installation of n°__ floodlights of type ________ on 360° crown, consisting of the following elements:

MAST

The mast is tapered with a polygonal section, made of S355 JR steel sheet cold-pressed and longitudinally welded. The welding is carried out with a qualified procedure according to UNI EN ISO 15614-1.

The mast is composed of three sections joined on-site using a self-locking slip-on-joint system.

The base section houses the winch system, accessible through a vandal-proof lockable door.

The base section is equipped with a suitably ribbed plate for connection to the foundation plinth by means of anchor bolts and is provided with an earthing system.

MOTORIZED MOBILE SYSTEM

The motorized mobile system is composed of:

- Pole head: positioned at the top of the mast, it hosts the pulley for the cable, the hook device for the floodlight ring, anti-rotation centering pins, and the socket body that ensures the electrical connection while keeping the power cables fixed inside the mast.

- Mobile crown: made of steel, circular in shape, supports the lighting bodies and related electrical equipment, and is fixed to the carriage.

- Carriage: made of steel, it runs along the guide fixed to the mast by means of slides/rollers and hooks to the pole head with two steel blades that support the weight of the crown during operation.

- Guide: made of lightweight alloy, fixed along the entire length of the mast, it allows the smooth movement of the carriage.

- Safety brake: the exclusive braking system is based solely on three stainless steel elements. During operation, the system is active, and during the ascent and descent of the carriage, the system is ready to intervene in case of cable slackening.

- Traction cable: made of high-strength galvanized steel, it is properly sized and fixed on one side to the carriage, and on the other side to the drum positioned at the base of the mast near the inspection door.

- Drive unit: fixed to the mast through a tilting device that allows tension control of the cable, it consists of a worm gear reducer combined with a pre-stage gear and driven by a removable electric motor. The drive unit is connected to the drum, allowing system movement through cable winding/unwinding.

- Removable motor: with characteristics of 0.75/1.5 kW – 3 phase – 50 Hz – 4 poles at 380 V depending on the load to be lifted. It is equipped with an electrical control panel and a low-voltage handheld pendant with a 5-meter power cable to ensure safe operation during movement; the pendant features stop, ascent, and descent commands. The motor is powered from the floodlights’ supply line. This system allows for the maintenance of multiple high masts simultaneously.

- Electrical accessories: the floodlights’ power supply line is made with a fixed cable inside the mast and can be sectioned via a fused interlocking switch. The number of conductors depends on the required number of switching circuits (standard: 1 circuit). The line starts from the interlocked socket inside the winch compartment and ends at the top of the mast at the female socket body.

- Protective dome: made of a semi-spherical fiberglass dome, externally protected by a gelcoat-pigmented gray paint layer, it is positioned at the top to protect the electrical and mechanical components.

FINISH

The entire steel structure is hot-dip galvanized, conforming to UNI EN ISO 1461.

1.4 Handling and Storage

The steel structures must be packaged, handled, and transported carefully to avoid permanent deformations and surface damage. Special attention should be given to reinforcing free ends and protecting machined surfaces.

1.5 Welding

The contractor must ensure welding quality as defined by UNI EN ISO 3834, following the execution class of the structures in accordance with NTC2018 Table 8.1, without falling below the safety standards outlined in Table 11.3.XI of NTC2018.

For execution classes EXC2, EXC3, and EXC4, welding activities must be coordinated by qualified Welding Coordinators in accordance with UNI EN ISO 14731.

1.5.1 Welder Qualification

All welders must be certified according to UNI EN ISO 9606-1, and operators according to UNI EN 14732.

1.6 Fabrication Tolerances

Fabrication tolerances are specified in the project drawings.

1.7 Assembly

The contractor must organize the construction site in a way that satisfies the technical requirements to ensure safe work conditions by addressing the following points:

- Use of lifting equipment

- Accessibility and site conditions

- Ground stability

- Knowledge of underground utilities, suspended cables, etc.

- Adjacent structures affecting the assembly process

- Cooperation procedures with other contractors on-site

- Utility availability

- Assembly activities must be approved by the Construction Manager.

- Refer to UNI EN 1090-2 §11.1 for assembly tolerances.

1.8 Protective Treatments

Material protection by hot-dip galvanizing must comply with UNI EN ISO 1461 and UNI EN ISO 14713 parts 1 and 2. Welds must be free of porosity, blowholes, and slag must be removed before galvanization. Post-galvanization bending or forming of parts is prohibited. Cut or drilled pieces must have the galvanization restored. Galvanized pieces must be inspected for defects, and the maximum area of non-galvanized parts should not exceed 0.5% of the total surface. Defects must be repaired according to UNI EN ISO 2063.

1.9 Caratteristiche dimensionali della torrefaro:

|

mm. | 25000 |

|

mm. | 850/25 |

|

mm. | 664/4 |

|

mm. | 180/4 |

|

Kg. | 1775 |