Article TF300P

Torrifaro a piattaforma fissa con piastra di base

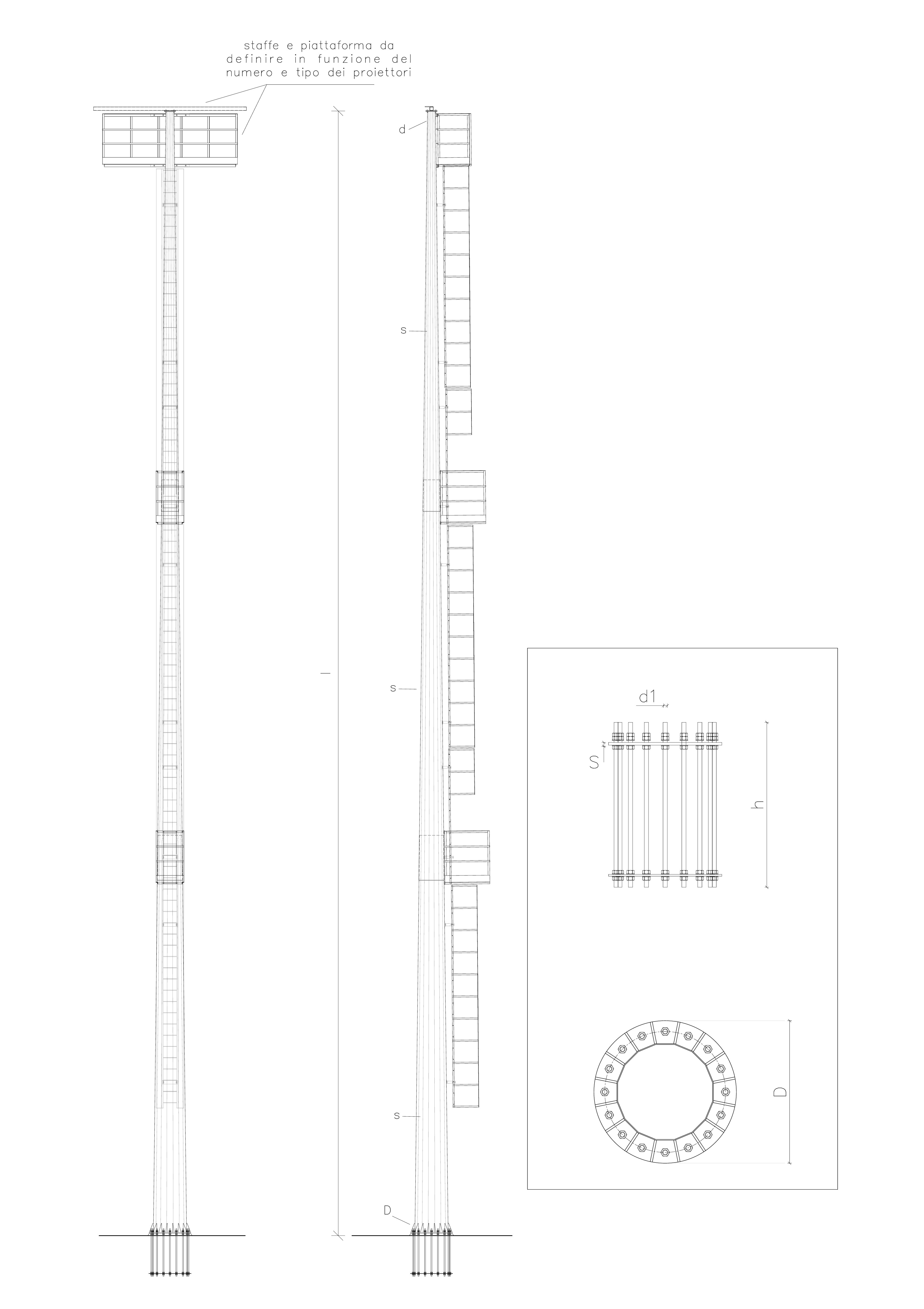

Fixed Platform High Mast with Base Plate

Ideal for sports facilities of any size and large areas, these structures offer a versatile and cost-effective solution.

They have a truncated conical shape with a polygonal section and are made of S355JR steel sheet (UNI EN 10025 standard) through press-bending and subsequent longitudinal welding. They consist of multiple sections, joined using the slip-on-joint method.

The fixed platform high masts with base plates are anchored to the foundation block using anchor bolts embedded in the concrete, provided they are equipped with a base plate welded to the lower section of the mast. The welds are carried out using procedures approved by the Italian Welding Institute, performed by qualified personnel, and tested in accordance with UNI EN 3834-2 standard.

Each high mast is equipped with an access ladder, which can be of three types:

- Modular curved ladder with full-length guardrail

- Modular curved ladder with full-length guardrail equipped with a central “T” guide, to be used with a CE-marked fall protection safety device

- Modular rung-type ladder, Safety type, equipped with a central “T” guide, to be used with a CE-marked fall protection safety device

The modular ladder is positioned behind the lighting face and attached to the mast using welded supports. At the top of the mast, there is a platform whose dimensions vary depending on the number of installed floodlights. The platform, accessible through a hatch in the walking surface, allows maintenance of the floodlights in safe conditions.

The mast is also equipped with a number of resting platforms that vary according to the height of the pole, fixed to the mast using welded supports. In towers using Safety ladders, resting platforms are provided.

The structures are CE-marked and manufactured in compliance with UNI EN 1090 standard with an execution class of EXC 2. The high masts are hot-dip galvanized by immersion in a zinc bath in compliance with UNI EN ISO 1461 standard. Upon customer request, powder coating is available, performed according to the UNI EN ISO 12944 standard.

|

m

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

kg

|

m²

|

m x m x m

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| TF300P | 30 | 1000/30 | 824 | 180 | 4 - 4 - 4 | 16/M27 | 1100 | 2252 | 50 | 3,70 × 3,70 × 1,60 |

-

The structure is manufactured according to the UNI EN 1090 standard in execution class EXC2, in compliance with CE certification.

-

The shaft is made of S355 JR steel, and the structural components are made of S235 JR steel, with characteristics compliant with the UNI EN 10025 standard, all hot-dip galvanized according to UNI EN 1461 standards. The supplied bolts are made of stainless steel cl.8.8, compliant with the UNI EN 898-1 standard.

-

Dimensional tolerances comply with the UNI EN 1090 standard.

-

- UNI EN 1461: Hot-dip galvanized coatings on finished ferrous products and steel articles.

- UNI EN 10025: Hot-rolled products of structural steels.

- UNI EN 3834: Quality requirements for fusion welding of metallic materials.

- UNI EN 1090-2: Execution of steel and aluminium structures. Part 2 – Technical requirements for steel structures.

- D.M. 17/01/2018: Update of Technical Standards for Construction.

- Circular No. 7 of 21/01/2019: Instructions for the application of D.M. 17/01/2018.

- Legislative Decree 81/2008: Consolidated text on occupational health and safety.

FIXED PLATFORM HIGH MAST, WITH BASE PLATE model TF300P

1 METAL STRUCTURES

1.1 Object

The works covered by this specification involve the supply of n. _ fixed high masts for lighting with a height of 30 meters above ground level, model TF300P by N.C.M. Srl, to be installed by direct insertion into the foundation block.

The structures will be located ___________

Nominal service life of the work (NTC 2018 Tab. 2.4.I): 50 anni

Usage class (NTC 2018 § 2.4.2): III

Execution class (UNI EN 1090-2): EXC2

1.2 Performance

The Contractor must provide the following services:

- Procurement of materials (profiles, sheets…)

- Prefabrication in the workshop

- Storage in the workshop

- Surface protection treatments (hot-dip galvanization)

- Material inspection documents

- CE marking of structural components

- Transportation to the site

- Workshop van equipped for assembly

- Ground assembly of the high mast and assistance with erection using a crane

- Mechanical installation of floodlights and accessories as specified in the final design

- Issuance of completion certificate

1.3 Description of the supply

The supply includes the following works:

Fixed high mast with a top platform, designed for the installation of n° __ floodlights, model ________, on a single face, composed of the following elements.

MAST

Of truncated conical shape with a polygonal section, it is made of press-bent and longitudinally welded S355 JR steel sheet. The welding is carried out in accordance with UNI EN ISO 3834 standard using a process approved by the Italian Welding Institute.

It consists of three sections to be joined on-site by overlapping them using the slip-on-joint method.

The base section is prepared for anchoring with a base plate on foundation bolts pre-cast into the foundation block and is equipped with a grounding plate.

LADDER WITH GUARDRAIL

The rung ladder, made of modular steel elements and equipped with a protective cage, is positioned on the axis of the mast behind the lighting face and is attached to it using bolted elements.

REST PLATFORM (n. 1)

Measuring 1000 x 620 mm, it is positioned along the same axis as the access ladder, equipped with an anti-slip grating floor, complete with a toe board and a closable access hatch, and a protective railing 1200 mm in height with an intermediate bracing.

MATERIALS

The shaft is made of S355 JR steel, and the structural components are made of S235 JR steel, with characteristics compliant with the UNI EN 10025 standard, all hot-dip galvanized according to UNI EN 1461 standards. The supplied bolts are made of stainless steel cl.8.8, compliant with the UNI EN 898-1 standard.

FINISHING

The entire structure, including all steel components, is hot-dip galvanized by immersion in a molten zinc bath, in accordance with UNI EN ISO 1461 standards.

1.4 Handling and storage

Steel structures must be carefully packaged, handled, and transported in such a way as not to cause permanent deformations or surface damage. Special care must be taken to reinforce free ends and protect machined surfaces.

1.5 Welding

The Contractor must ensure that welding is carried out at the appropriate quality level as defined by UNI EN ISO 3834 standard and according to the execution class of the structures.

For execution classes EXC2, EXC3, and EXC4, the coordination of welding activities must be managed by qualified Welding Coordinators according to UNI EN ISO 14731.

1.5.1 Welder qualification

All employed welders must be certified and qualified according to UNI EN ISO 9606-1, and operators according to UNI EN 14732.

1.6 Manufacturing tolerances

Manufacturing tolerances are indicated in the project drawings.

1.7 Assembly

The Contractor must organize the site to meet the technical requirements that ensure work safety by addressing the following points:

- Use of lifting equipment

- Road access and site conditions

- Ground conditions

- Possible settling of structure assembly supports

- Detailed knowledge of underground utilities, suspended cables, or other obstacles

- Adjacent structures that could influence assembly

- Coordination procedures with other contractors on-site

- Utility availability

Assembly activities must be approved by the Construction Supervisor. For assembly tolerances, refer to UNI EN 1090-2.

1.8 Protective treatments

The protection of materials by hot-dip galvanization must comply with UNI EN ISO 1461 and UNI EN ISO 14713 parts 1 and 2.

Welds of structural elements to be galvanized must be free of porosity and blowholes, and any slag must be removed before galvanizing. Bending and mechanical forming of hot-dip galvanized pieces are prohibited. If cutting or drilling of galvanized pieces is performed, the galvanization must be restored. For elements composed of loose parts assembled by welding, pairs of vent holes with a diameter no less than 10 mm must be provided.

The minimum thickness of the zinc coating must comply with UNI EN 1461.

Galvanized parts must be inspected for defects, and the maximum extent of defective areas must not exceed the limits indicated in UNI EN ISO 1461. In particular, uncoated areas must not exceed 0.5% of the element’s surface, and each area to be repaired must not be larger than 10 cm². Repairs must be carried out according to UNI EN ISO 2063.

1.9 Dimensional Characteristics of the High Mast:

| Above ground height | mm. | 30000 |

| Base plate / thickness | mm. | 1000/30 |

| Ø Base / thickness | mm. | 824/4 |

| Ø Top / thickness | mm. | 180/4 |

| Weight | Kg. | 2252 |