Article SQ6070

Square crossbars

|

Description

|

mm

|

mm

|

Kg

|

|

|---|---|---|---|---|

| SQ6070 | Square crossbars for poles with a 60mm top. | 600 | 70 | 16 |

-

The crossbars are marked “CE” through the application of an adhesive label (no. 1608 CPD P028).

The crossbars are produced by a company certified UNI EN ISO 9001:2015 and authorized to issue the CE marking, in compliance with the applicable legislation (EU Regulation No. 305/2011). The label, confirming conformity with the CE standards and applied to each pole, must include: reference standard EN 40-5, manufacturer’s code, year of manufacture, product code, and the CE marking authorization certificate number.

-

The crossbars are made of S235 JR steel, with characteristics in accordance with the UNI EN 10219 standard.

-

The dimensional tolerances comply with the UNI EN 1090 standard.

-

- UNI EN 1461: Hot-dip galvanized coatings on fabricated iron and steel articles.

- UNI EN 10025: Hot rolled products of structural steels.

- UNI EN 10219-1-2: Cold-formed welded structural hollow sections of non-alloy and fine grain steels.

- UNI EN 3834: Quality requirements for fusion welding of metallic materials.

- UNI EN 1090-2: Execution of steel and aluminium structures. Part 2 – Technical requirements for steel structures.

- D.M. 17/01/2018: Update of the Technical Standards for Construction.

- Circular no. 7 of 21/01/2019: Instructions for the application of D.M. 17/01/2018.

- Legislative Decree 81/2008: Consolidated Act on Health and Safety at Work.

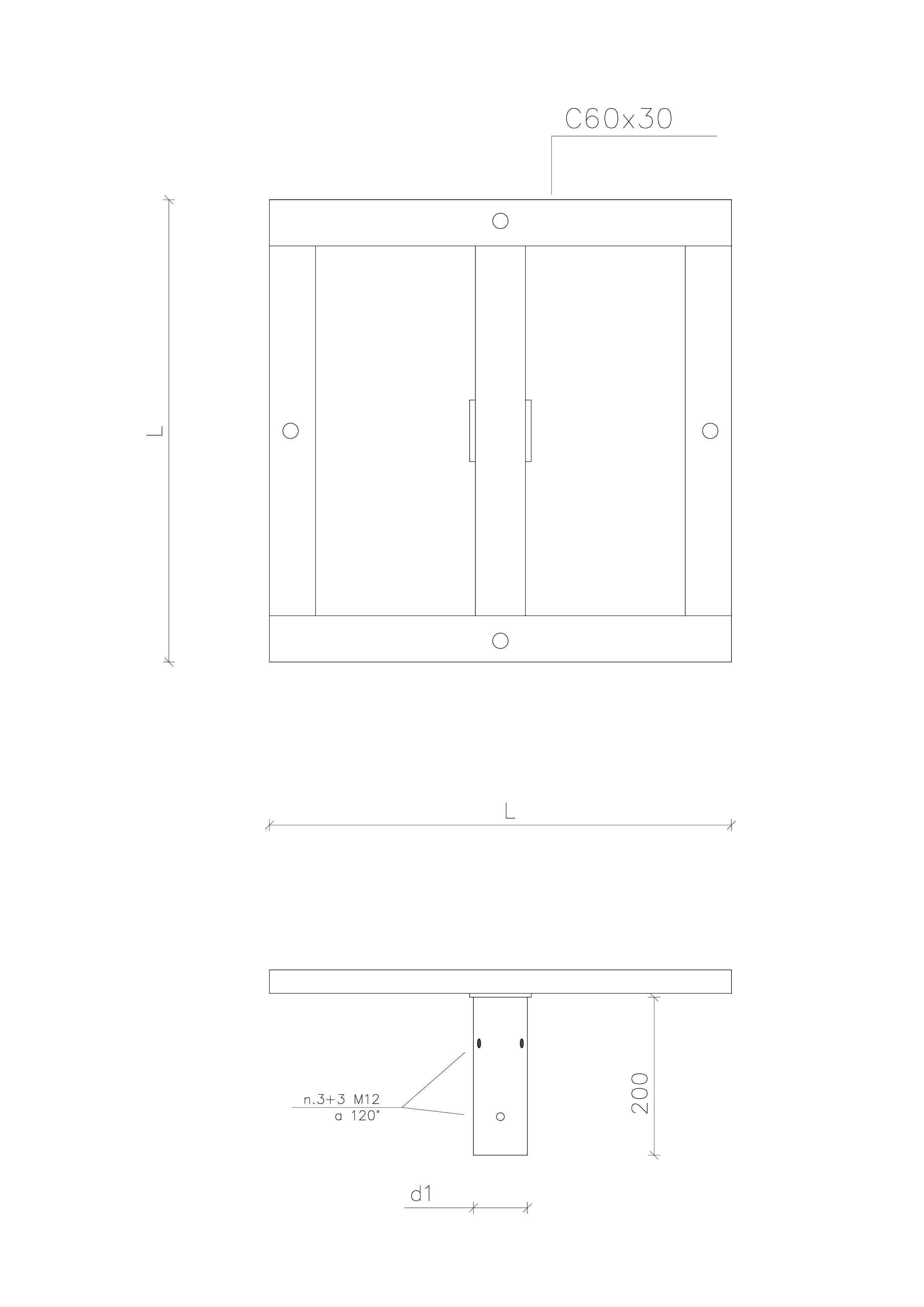

SQUARE CROSSBARS model SQ6070

The square crossbars, model SQ6070, produced by NCM, are made using a U-shaped hollow profile welded to a tube that is fixed to the top of the pole with 6 M10 bolts. The material used for construction is S235JR steel. They are supplied hot-dip galvanized in a molten zinc bath, in accordance with the UNI EN ISO 1461 standard.

Dimensional characteristics of the square crossbar:

| Side | : | mm | 600 |

| Insertion diameter | : | mm | 70 (for poles with a 60mm top) |

| Profile | : | “U” | 60×30 |

Dimensional tolerances: UNI EN 1090.

Any painting, following galvanization, in a color chosen by the Project Management, is carried out using a thermosetting powder coating process. Each product will be protected with bubble wrap.