Article SE04

Poles for traffic-lights SEO

Traffic light poles are vertical structures used to support traffic signals, which regulate the flow of vehicular and pedestrian traffic at intersections or other critical points in road circulation. These poles are designed to ensure the visibility of traffic signals and to provide effective and safe traffic control.

|

m

|

m

|

mm

|

mm

|

mm × mm

|

mm

|

mm

|

mm

|

kg

|

m²

|

m x m x m

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| SE04 | 6,6 | 0,8 | 180 | 114 | 186 × 45 | 4000 | 4 | 4 | 163 | 4,78 | 1,40 × 1,40 × 1,10 |

-

The poles are “CE” marked by applying an adhesive label (no. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must indicate the following: reference standard EN 40-5, manufacturer’s initials, year of manufacture, product code, and the certification number authorizing CE marking.

-

The semaphore poles are made of S235JR and S355JR steel (compliant with UNI EN 10025 standard).

-

The tolerances are compliant with the EN40-2 standard.

-

- UNI EN 1461 – Hot-dip galvanized coatings on finished ferrous products and steel articles.

- UNI EN 10025 – Hot rolled products of structural steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Welding procedure test.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 40 – Lighting columns.

Part 2 – Part 3.

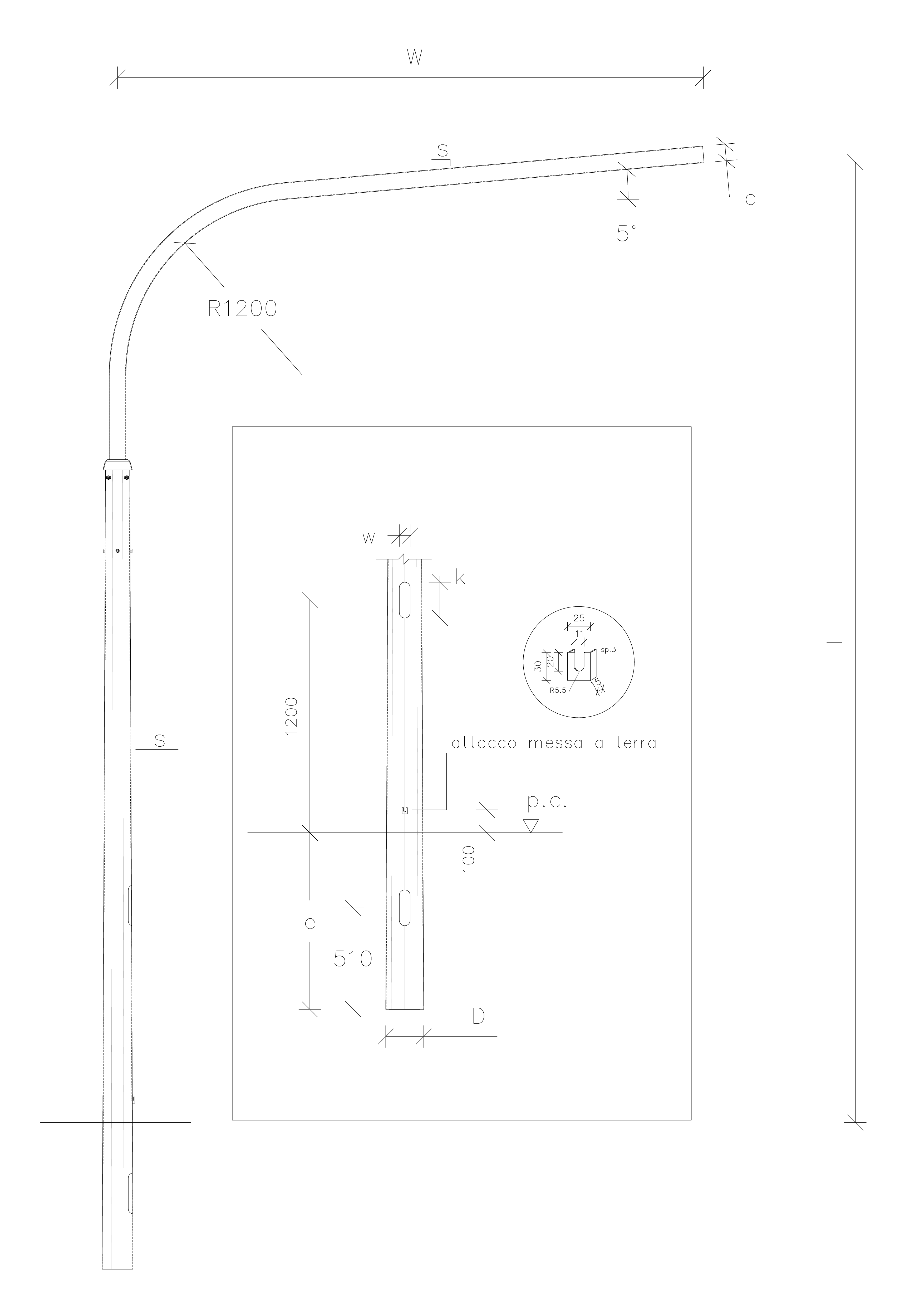

TRAFFIC LIGHT POLE model SE04

The buried traffic light pole model SE04, manufactured by NCM, consists of two parts: a straight octagonal base section and a circular curved arm tapered in multiple sections. The base is made of a straight octagonal section pole, created from cold-formed steel sheet by press-bending and longitudinally welded using an automatic welding process. The curved outreach arm, circular in section and tapered in multiple welded segments, is attached to the pole by bolts and a self-centering ring.

The pole is equipped with the following standard features:

- Hot-dip galvanization by immersion in molten zinc, in compliance with UNI EN ISO 1461.

- Cable entry hole positioned at 510 mm from the base, measuring 186×45 mm.

- Grounding support welded to the pole for an M10 bolt, located 900 mm from the base.

- Slot for the terminal block, measuring 186×45 mm, with the center located at 2000 mm from the base.

- Four cable passage holes, 20 mm in diameter, positioned at 90° and located 3100 mm above ground level.

Materials:

The traffic light poles are made of S235JR and S355JR steel (in accordance with the UNI EN 10025 standard).

The dimensional tolerances comply with the EN 40-2 standard.

Dimensional characteristics of the pole:

| Maximum height above ground | : | mm | 6600 |

| Burying | : | mm | 800 |

| Octagonal base diameter | : | mm | 180 |

| Octagonal base thickness | : | mm | 4 |

| Cylindrical arm diameter | : | mm | 114 |

| Arm thickness | : | mm | 4 |

| Arm projection | : | mm | 4000 |

CE Marking:

The poles are “CE” marked by applying an adhesive label (no. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must indicate the following: reference standard EN 40-5, manufacturer’s initials, year of manufacture, product code, and the certification number authorizing CE marking.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.