Article RS07193LA

Stepped poles for overhead lines

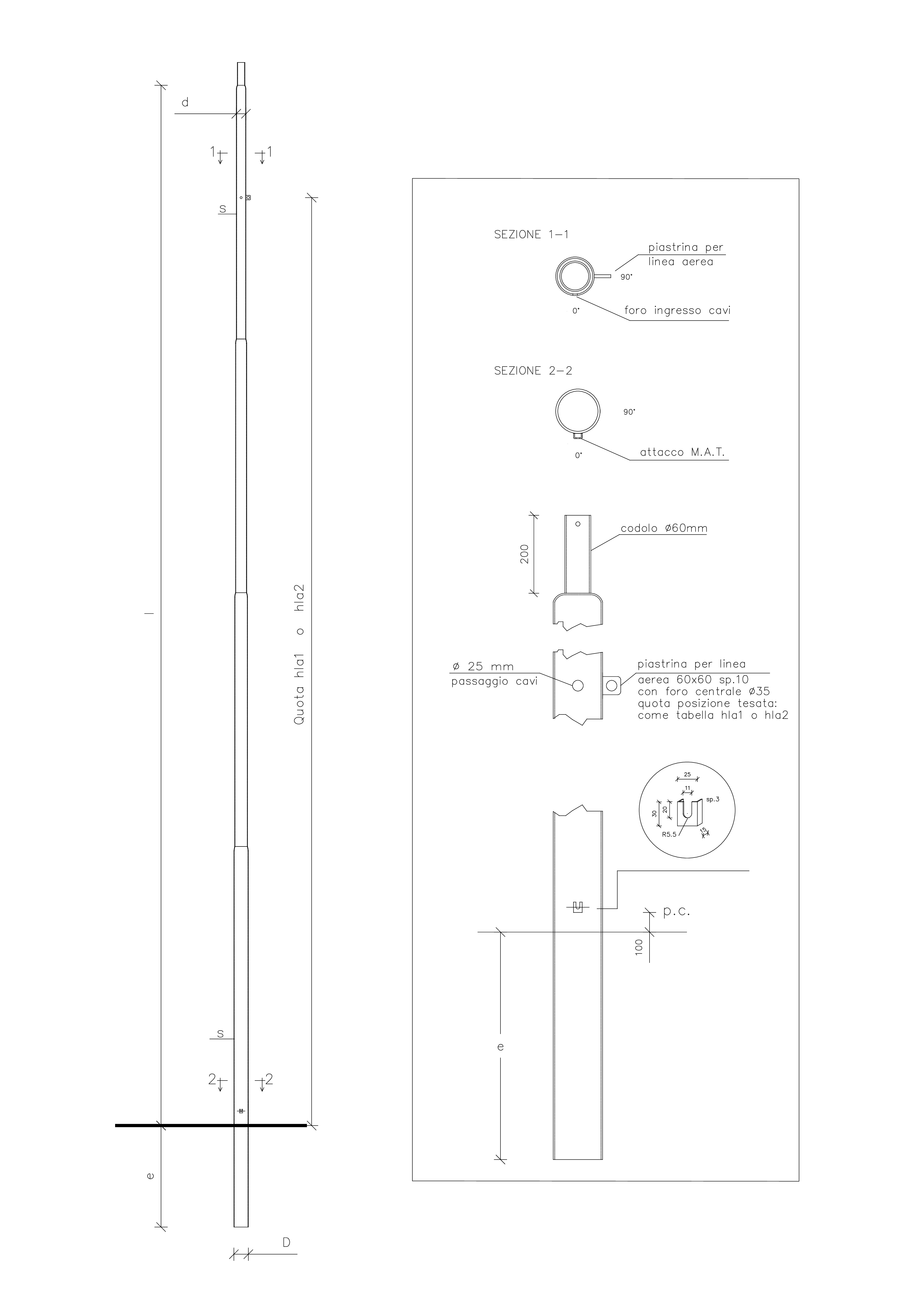

The stepped pole for overhead lines is a solution designed for the safe and efficient support of suspended electrical cables, ideal for use in both urban and rural environments. Made of S235JR steel compliant with the UNI EN 10219 standard, the pole is composed of cylindrical tubes joined by circumferential welds at the stepped sections, ensuring a robust and durable structure over time.

The stepped design, which involves a gradual reduction of the diameter towards the upper end, optimizes load distribution, reducing weight while maintaining high mechanical strength. The pole is hot-dip galvanized according to UNI EN ISO 1461, providing long-lasting protection against corrosion and wear caused by weather conditions.

Thanks to its versatile design and compliance with high safety standards, the stepped pole is a reliable choice for supporting overhead electrical lines, ensuring stability and functionality even in challenging environmental conditions.

|

m

|

m

|

mm

|

mm

|

mm

|

m

|

daN

|

m

|

daN

|

kg

|

m²

|

m × m × m

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RS07193LA | 6 | 0,8 | 193 | 114 | 4-3 | 5,5 | 170 | - | - | 110 | 3,48 | 1,30 × 1,30 × 0,90 |

-

The poles are CE marked through the application of an adhesive label (No. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue the CE marking in compliance with the current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must display: reference standard EN 40-5, manufacturer’s initials, year of production, product code, and the CE marking authorization certificate number.

-

The poles are made of S235 JR steel with characteristics conforming to the UNI EN 10219 standard.

-

The dimensional tolerances comply with the EN 40-2 standard.

-

- UNI EN 1461 – Hot-dip galvanizing coatings for finished ferrous products and steel articles.

- UNI EN 10219 – Cold-formed welded hollow sections for structural applications of non-alloy and fine-grain steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Qualification testing of welding procedures.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 40 – Poles for public lighting. Part 2 – Part 3.

STEPPED POLE FOR AERIAL LINES Model RS07193LA

The pole includes the following standard features:

. Hot-dip galvanization by immersion in molten zinc in accordance with the UNI EN ISO 1461 standard.

. Cable entry hole with a diameter of 25 mm positioned at 90° to the support for the aerial line.

. Support for the aerial line consisting of a plate with a through hole of 35 mm in diameter.

. Grounding support for M10 bolt located 900 mm from the base.

. Terminal stub for accessory/street lighting support with a diameter of 60 mm and a length of 200 mm.

Materials: The poles are made of S235JR steel with characteristics in accordance with the UNI EN 10219 standard.

Dimensional tolerances: The dimensional tolerances conform to the EN40-2 standard.

Dimensional Characteristics of the Pole:

| Above ground height | : | mm | 6000 |

| Burying | : | mm | 800 |

| Base diameter | : | mm | 193 |

| Top diameter | : | mm | 114 |

| Thickness | : | mm | 4-3 |

| Overhead line height hla1 | : | mm | 5500 |

| Maximum load capacity T1 | : | daN | 170 |

| Overhead line height hla2 | : | mm | – |

| Maximum load capacity T2 | : | daN | – |

The pole is suitable for supporting a single force, the height of the force determines the maximum applicable stress.

CE Marking:

The poles are CE marked through the application of an adhesive label (No. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue the CE marking in compliance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must display: reference standard EN 40-5, manufacturer’s initials, year of production, product code, and the CE marking authorization certificate number.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.