Article R09P

Stepped lighting poles

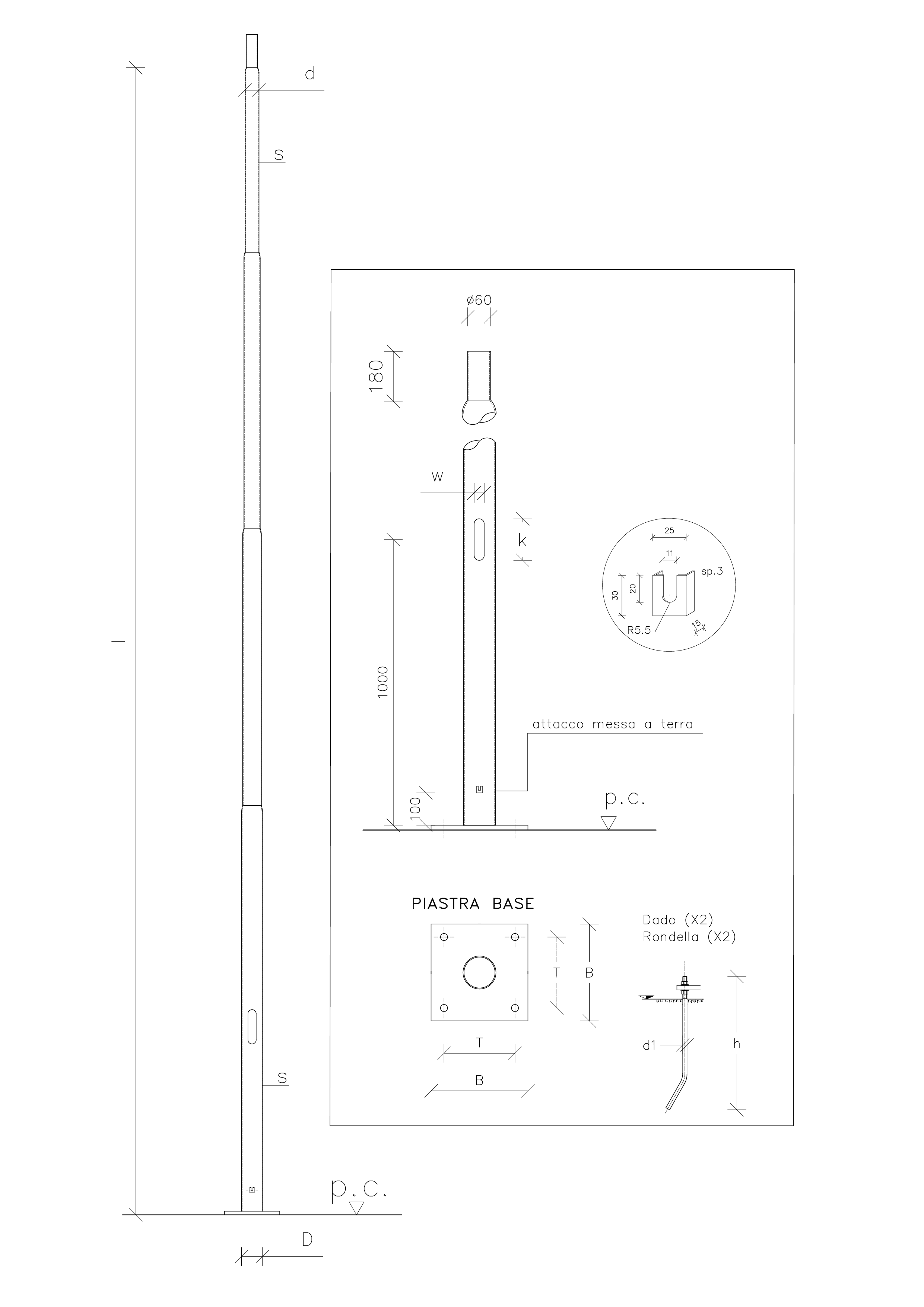

The stepped pole, complete with a welded base plate, is made by joining tubes of different diameters, appropriately processed at the ends. These tubes are assembled using an automatic circumferential welding process.

|

m

|

mm

|

mm

|

mm

|

mm × mm

|

mm

|

mm

|

mm

|

mm

|

kg

|

m²

|

m × m × m

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R09P | 9 | 139 | 76 | 3 | 186 × 45 | 300 | 220 | M18 | 500 | 85 | 3,04 | 1,20 × 1,20 × 0,80 |

-

The poles are CE marked through the application of an adhesive label (No. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue the CE marking in compliance with the current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must display: reference standard EN 40-5, manufacturer’s initials, year of production, product code, and the CE marking authorization certificate number.

-

The poles are made of S235 JR steel with characteristics conforming to the UNI EN 10219 standard.

-

The dimensional tolerances comply with the EN 40-2 standard.

-

- UNI EN 1461 – Hot-dip galvanizing coatings for finished ferrous products and steel articles.

- UNI EN 10219 – Cold-formed welded hollow sections for structural applications of non-alloy and fine-grain steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Qualification testing of welding procedures.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 40 – Poles for public lighting. Part 2 – Part 3.

STEPPED WELDED POLE Model R09P

The stepped pole model R09P, with a welded base plate, manufactured by NCM, is made by coupling induction-welded tubes of different diameters, properly machined at the ends. These are then assembled using an automatic circumferential welding process.

The pole is provided with the following standard features:

. Hot-dip galvanization in accordance with UNI EN ISO 1461.

. Welded base plate.

. Grounding support for M10 bolt located 100 mm from the base.

. Slot for terminal block measuring 186×45 mm, with centerline at 1000 mm from the base.

Materials:

The poles are made of S235 JR steel, compliant with UNI EN 10219 standards. Dimensional tolerances comply with EN 40-2.

Pole Dimensions:

| Above ground height | : | mm | 9000 |

| Base plate | : | mm | 300×300 |

| Base diameter | : | mm | 139 |

| Base thickness | : | mm | 3 |

| Top diameter | : | mm | 76 |

| Top thickness | : | mm | 3 |

CE Marking:

The poles are CE marked through the application of an adhesive label (No. 1608 CPD P028).

The pole is manufactured by a company certified under UNI EN ISO 9001:2015 and authorized to issue the CE marking in compliance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must display: reference standard EN 40-5, manufacturer’s initials, year of production, product code, and the CE marking authorization certificate number.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.