Article POT134P

Polygonal lighting poles

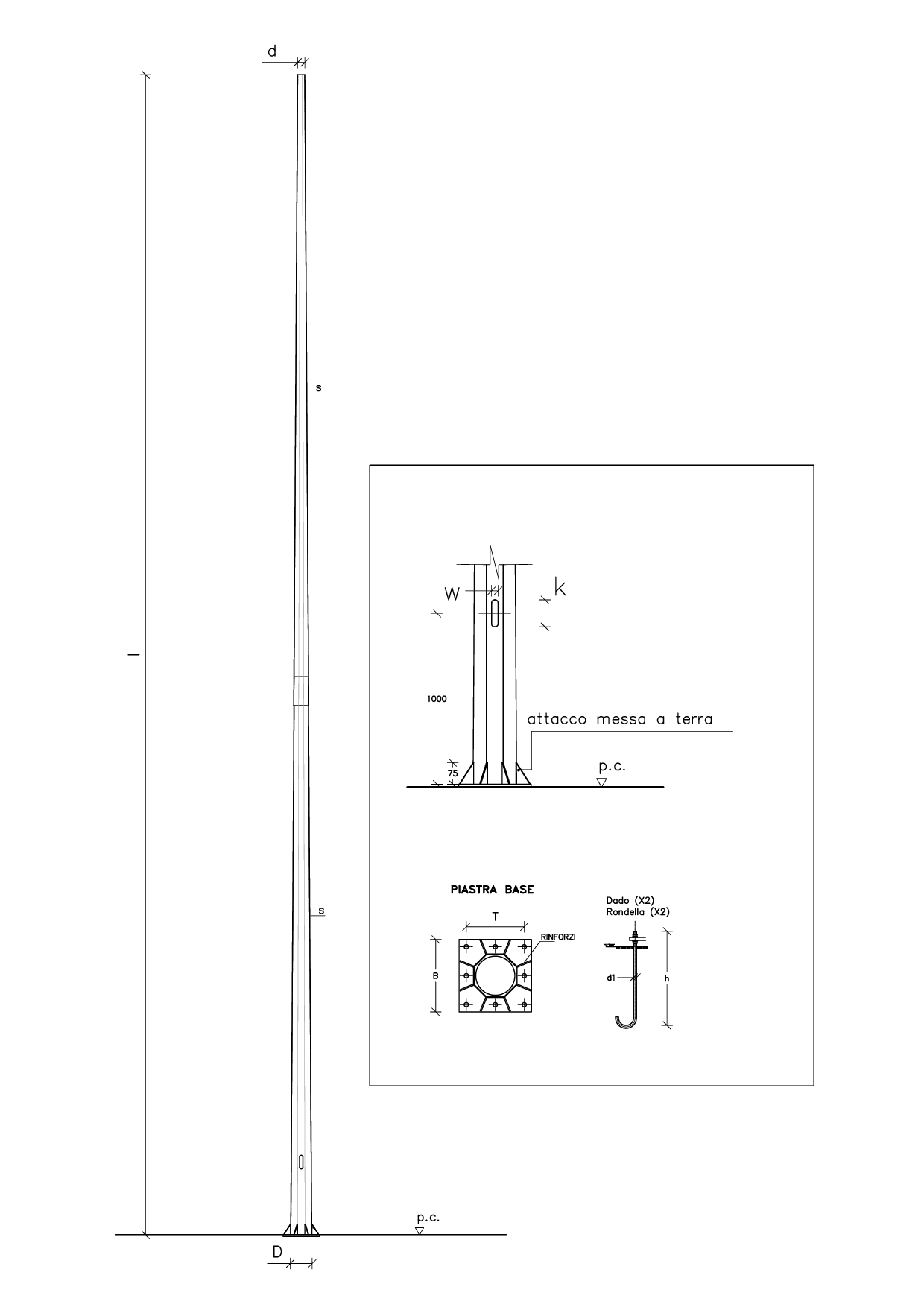

The conical octagonal pole is made from sheet metal that is cut and press-bent, with the edges joined and longitudinally welded using an automatic welding process.

|

m

|

n

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

n/mm

|

mm

|

kg

|

m²

|

m x m x m

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| POT134P | 13 | 8 | 269 | 100 | 4 | 186 × 45 | 450 | 350 | 8/M24 | 850 | 291 | 7,73 | 1,90 × 1,90 × 1,10 |

-

The poles are CE marked by applying an adhesive label (no. 1608 CPD P028).

The pole is produced by a company certified according to UNI EN ISO 9001:2000 and authorized to issue the CE marking in compliance with current legislation (DPR 246/93, 89/106/EEC, 93/68/EEC). The label, certifying conformity with CE standards and affixed to each pole, must include: the reference standard EN 40-5, the manufacturer’s code, the year of production, the product code, and the number of the CE marking authorization certificate.

-

The poles are made of S235 JR steel, with characteristics compliant with the UNI EN 10025 standard.

-

The dimensional tolerances comply with the EN 40-2 standard.

-

- UNI EN 1461 – Hot-dip galvanizing coatings on finished iron products and steel items.

- UNI EN 10025 – Hot-rolled products of structural steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Qualification testing of welding procedures.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 40 – Poles for public lighting. Part 2 – Part 3.

WELDED POLYGONAL POLE (8 sides) model POT134P

The octagonal-section polygonal pole with a welded base plate, model POT134P, produced by NCM, is made from sheet metal that is cut and press-bent, with the edges joined and longitudinally welded using an automatic welding process.

The pole, made in two sections, is provided with the following standard features:

. Hot-dip galvanization by immersion in molten zinc, in compliance with UNI EN ISO 1461.

. Grounding support for M10 bolt, positioned 100 mm from the base.

. Welded base plate.

. Slot for terminal block, measuring 186×45 mm, centered at 1000 mm from the base.

Materials:

The poles are made of S235 JR steel with characteristics conforming to UNI EN 10025.

The dimensional tolerances comply with the EN 40-2 standard.

Dimensional characteristics of the pole:

| Above ground height | : | mm | 13000 | |

| Base plate | : | mm | 450×450 | |

| Base diameter | : | mm | 269 | |

| Top diameter | : | mm | 100 | |

| Thickness | : | mm | 4 |

CE Marking:

The poles are CE marked by applying an adhesive label (no. 1608 CPD P028).

The pole is produced by a company certified according to UNI EN ISO 9001:2000 and authorized to issue the CE marking in compliance with current legislation (DPR 246/93, 89/106/EEC, 93/68/EEC). The label, certifying conformity with CE standards and affixed to each pole, must include: the reference standard EN 40-5, the manufacturer’s code, the year of production, the product code, and the number of the CE marking authorization certificate.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.