Article GT121152

Protective tapes

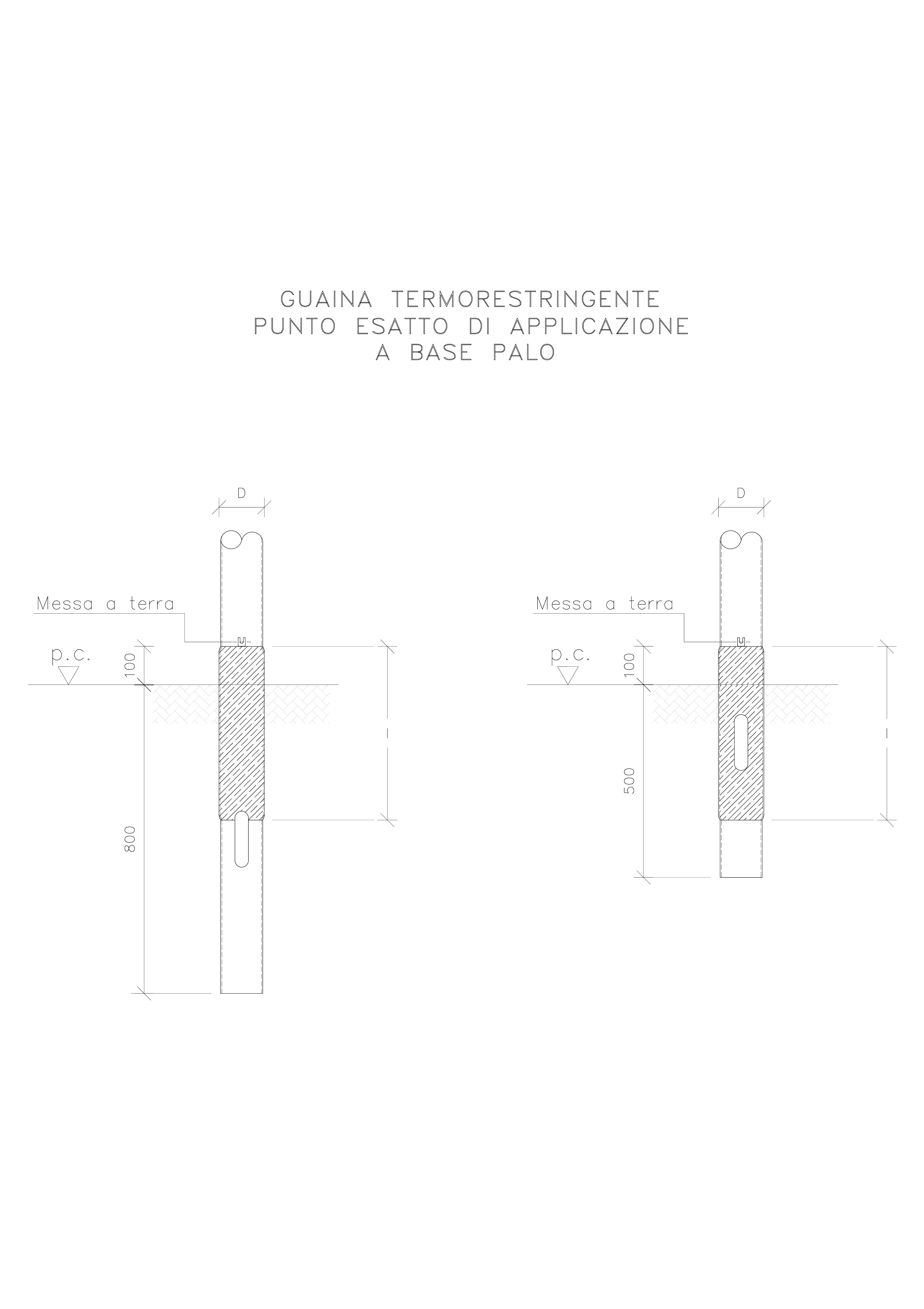

The heat shrinkable tubular sleeve provided by NCM, installed in the joint section, offers excellent protection for steel poles. Thanks to its high-strength adhesive and cross-linked high-density polyethylene support, it ensures reliable sealing and secure defense against moisture infiltration. The ease of installation, which does not require special equipment, along with the visual check of proper heating and shrinkage, makes it a practical and reliable solution. With outstanding resistance to temperature variations, ground stress, and chemical attacks, the heat shrinkable tubular sleeve provides the pole with effective and long-lasting protection.

The heat shrinkable sleeve is produced by a company certified UNI EN ISO 9001:2000 and authorized to issue the CE marking.

|

Descrizione

|

mm

|

Ø

|

|

|---|---|---|---|

| GT121152 | Heat shrink polyethylene sleeve applied hot. | 450 | 121 - 152 |

-

The heat shrinkable tubular sleeve is CE marked.

-

The heat shrinkable tubular sleeve is made of cross-linked high-density polyethylene.

-

- UNI EN 1461 – Hot dip galvanizing coatings for finished ferrous products and steel articles.

- UNI EN 10219 – Cold-formed welded structural hollow sections of non-alloy and fine grain steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Qualification tests of welding procedures. Part 1: Arc and gas welding of steels.

- UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification. Part 2: Gas welding.

- UNI EN40 – Street lighting columns. Part 2 – Part 3.

HEAT SHRINK SLEEVE model GT6076

The heat shrinkable tubular sleeve, model GT6076, supplied by NCM, is placed in the joint section to provide excellent protection for steel poles. Thanks to its high-resistance adhesive and high-density cross-linked polyethylene support, it ensures reliable sealing and secure defense against moisture infiltration. Its simple installation does not require special equipment, allowing for visual verification of correct heating and shrinkage, making it a practical and reliable solution.

With exceptional resistance to temperature variations, ground stress, and chemical attacks, the heat shrinkable tubular sleeve ensures effective and long-term protection for the pole, preserving its integrity over time.

Technical Data:

| Property | Test Method | Typical Value |

| Support | ||

| Tensile Strength at Break | ASTM D-638 | 22.8 MPa |

| Elongation at Break | ASTM D-638 | 600% |

| Hardness, Shore D | ASTM D-2240 | 57 |

| Shrink Force | ASTM D-638, 150°C | 0.276 MPa |

| Thermal Aging followed by Elongation | ASTM D-3045, 150°C ASTM D-638, 23°C | 21 days > 450% |

| Moisture Absorption | ASTM D-570 | 0.04% |

| Adhesive | ||

| Softening Point | ASTM E-28 | 135°C |

| Cut-off Rate | EN 12068 | 0.09 N/mm² |

| Installed Sleeve | ||

| Peel to PE | EN 12068, 10mm/min DIN 30672, 100mm/min | 1.1 N/mm 40 N/cm |

| Soil Stress Resistance | EN 489 – 100 cycles* | Pass |

| External Pressure Test after Soil Stress | EN 489 23°C, 30 kPa, 24 hrs | Pass |

Dimensional characteristics of the heat shrink sleeve:

| Length | : | mm | 450 |

| Diameter range covered | : | mm | from Ø 121 to Ø 152 |