Article ALS07R

Standard Bearer Poles

Standard bearer poles are designed for the display and raising of standards, commonly used in government buildings, schools, institutions, parks, and other public spaces. Characterized by a tapered shape that narrows towards the top, these poles offer structural stability and an aesthetically pleasing appearance.

Made from S235JR steel (in compliance with UNI EN 10219), the standard bearer poles can vary in height and diameter to suit the specific visibility requirements of the standard. They are fixed to the ground using a concrete foundation base or, if necessary, by anchoring with tie rods and a steel plate welded to the base of the pole.

Protected by hot-dip galvanizing to withstand weather conditions and available with painting upon request, the poles are equipped with accessories such as a rotating arm that allows the standard to withstand wind forces without being damaged.

In addition to their practical function of displaying standards, these poles play an important role in urban design, representing the identity and pride of a place or organization. They are often used for decorative, advertising, or commemorative purposes.

|

m

|

m

|

mm

|

mm

|

mm

|

kg

|

m²

|

m x m x m

|

|

|---|---|---|---|---|---|---|---|---|

| ALS07R | 6 | 0,8 | 127 | 76 | 3 | 58 | 2,37 | 1,20 × 1,20 × 0,90 |

-

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard UNI EN 1090-1, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

-

The poles are made from S235JR steel, with characteristics conforming to UNI EN 10219 standards.

-

Dimensional tolerances comply with the UNI EN 1090 standard.

-

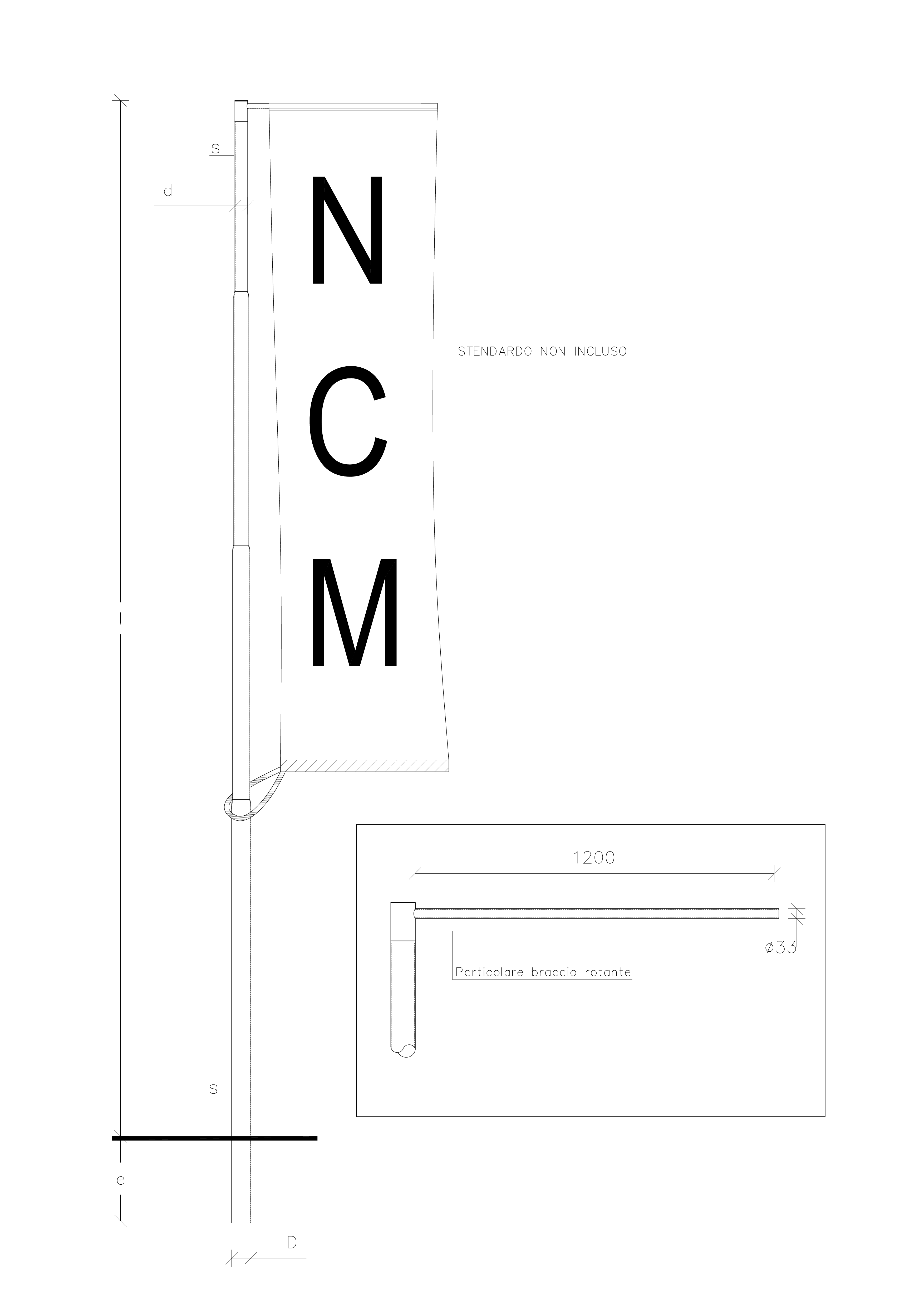

STEPPED STANDARD BEARER POLE, model ALS07R

The buried tapered standard bearer pole model ALS07R, produced by NCM, is made by joining longitudinally welded induction tubes of different diameters, with the ends appropriately processed. These tubes are assembled using an automatic circumferential welding process.

The pole includes the following standard features:

. Hot-dip galvanization by immersion in molten zinc, in compliance with UNI EN ISO 1461.

. Rotating standard bearer arm with a diameter of 27 mm and an extension of 1200 mm, applied at the top.

Materials:

The poles are made of S235 JR steel with characteristics conforming to UNI EN 10219.

The dimensional tolerances comply with the UNI EN 1090 standard.

Dimensional characteristics of the pole:

| Above ground height | : | mm | 6000 |

| Burying | : | mm | 800 |

| Base diameter | : | mm | 127 |

| Base thickness | : | mm | 3 |

| Top diameter | : | mm | 76 |

| Top thickness | : | mm | 3 |

CE Marking:

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard UNI EN 1090-1, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.