Article AL11C

Conical flagpoles

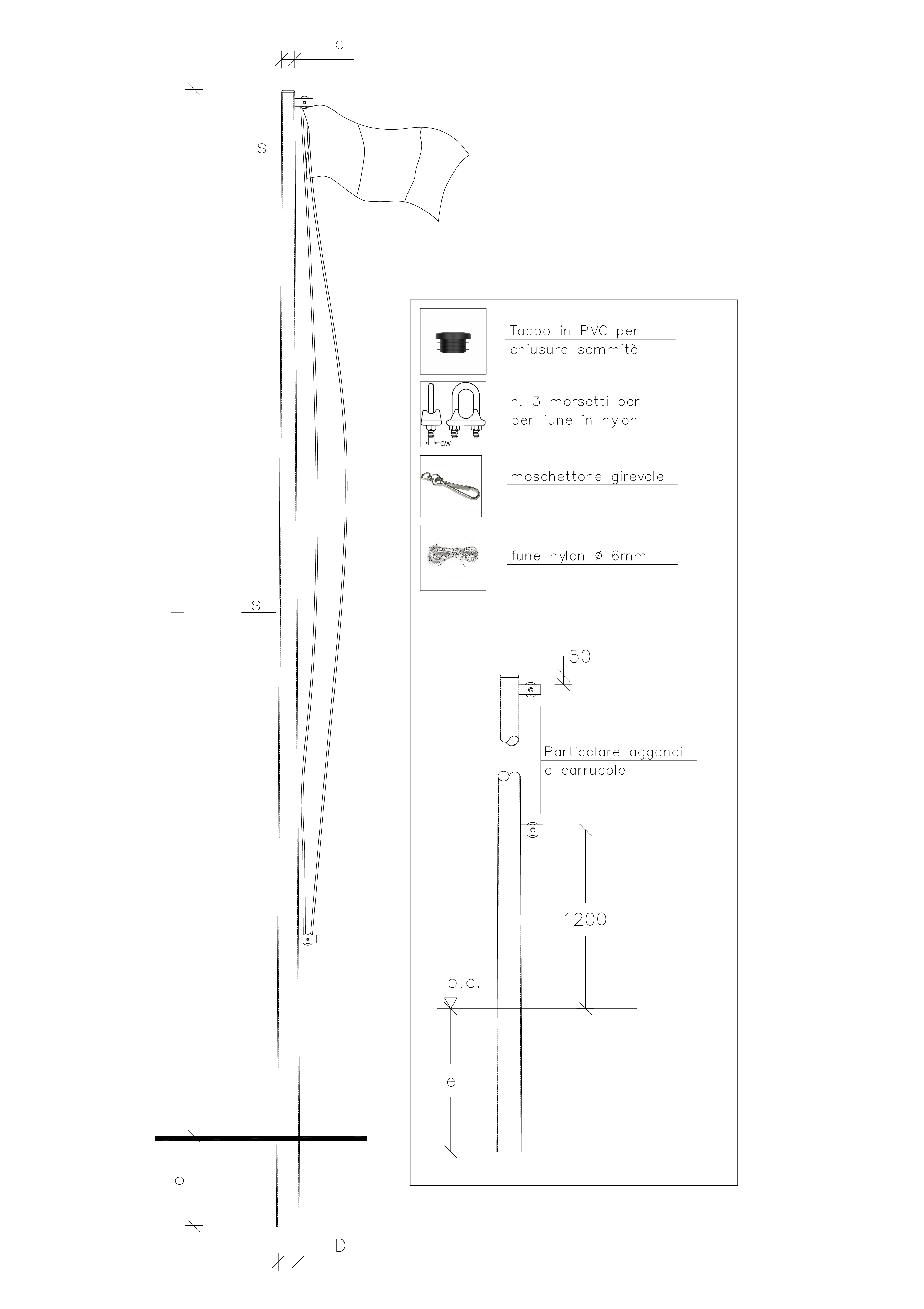

Conical flag poles are structures designed for the display and raising of flags, commonly used in government buildings, schools, institutions, parks, and other public spaces. They feature a conical shape made from S235JR steel (compliant with UNI EN 10025 standards), which offers an aesthetically pleasing appearance.

These poles vary in height and diameter to meet visibility requirements for the flag and are anchored to the ground using a concrete foundation. Protected by hot-dip galvanization and optionally painted upon request, they include accessories such as pulleys, ropes, and clamps for securing the flags.

In addition to their practical function of raising flags, conical flag poles represent the identity of a place or organization, blending harmoniously with urban design.

|

m

|

m

|

mm

|

mm

|

mm

|

kg

|

m²

|

mm x mm x mm

|

|

|---|---|---|---|---|---|---|---|---|

| AL11C | 10 | 0,8 | 168 | 60 | 3 | 93 | 3,87 | 1,30 × 1,30 × 0,90 |

-

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard UNI EN 1090-1, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

-

The poles are made from S235 JR steel, with characteristics conforming to UNI EN 10025 standards.

-

The dimensional tolerances comply with the UNI EN 1090 standard.

-

- UNI EN 1461 – Hot-dip galvanizing coatings on finished ferrous products and steel items.

- UNI EN 10025 – Hot-rolled products of structural steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Welding procedure qualification tests.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 1090-2 – Execution of steel and aluminum structures.

Part 2: Technical requirements for steel structures.

CONICAL FLAG POLE, model AL11C

The buried conical flagpole, model AL11C, produced by NCM, is made from cut and press-bent steel sheets, with the edges welded longitudinally using an automatic welding process.

The pole includes the following standard features:

. Hot-dip galvanization by immersion in molten zinc, in accordance with UNI EN ISO 1461.

. Steel supports for pulleys, welded at the top and 1 meter above the ground to operate the flag’s raise/lower system.

. A pair of nylon pulleys positioned on the shaped supports.

. Polyester rope of adequate length.

. Clamps for securing the flags.

. PVC cap at the top.

Materials:

The poles are made of S235 JR steel with characteristics conforming to UNI EN 10025.

The dimensional tolerances comply with the UNI EN 1090 standard.

Dimensional characteristics of the pole:

| Above ground height | : | mm | 10000 |

| Burying | : | mm | 800 |

| Base diameter | : | mm | 168 |

| Top diameter | : | mm | 60 |

| Thickness | : | mm | 3 |

CE Marking

The poles are CE marked through the application of an adhesive label (No. 1608 CPD P028).

The pole is produced by a company certified under UNI EN ISO 9001:2015 and authorized to issue the CE marking, in compliance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE regulations and affixed to each pole, must display: reference standard UNI EN 1090-1, manufacturer’s initials, year of production, product code, and the CE marking authorization certificate number.

Any additional painting, after galvanization, with colors chosen by the Project Supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.