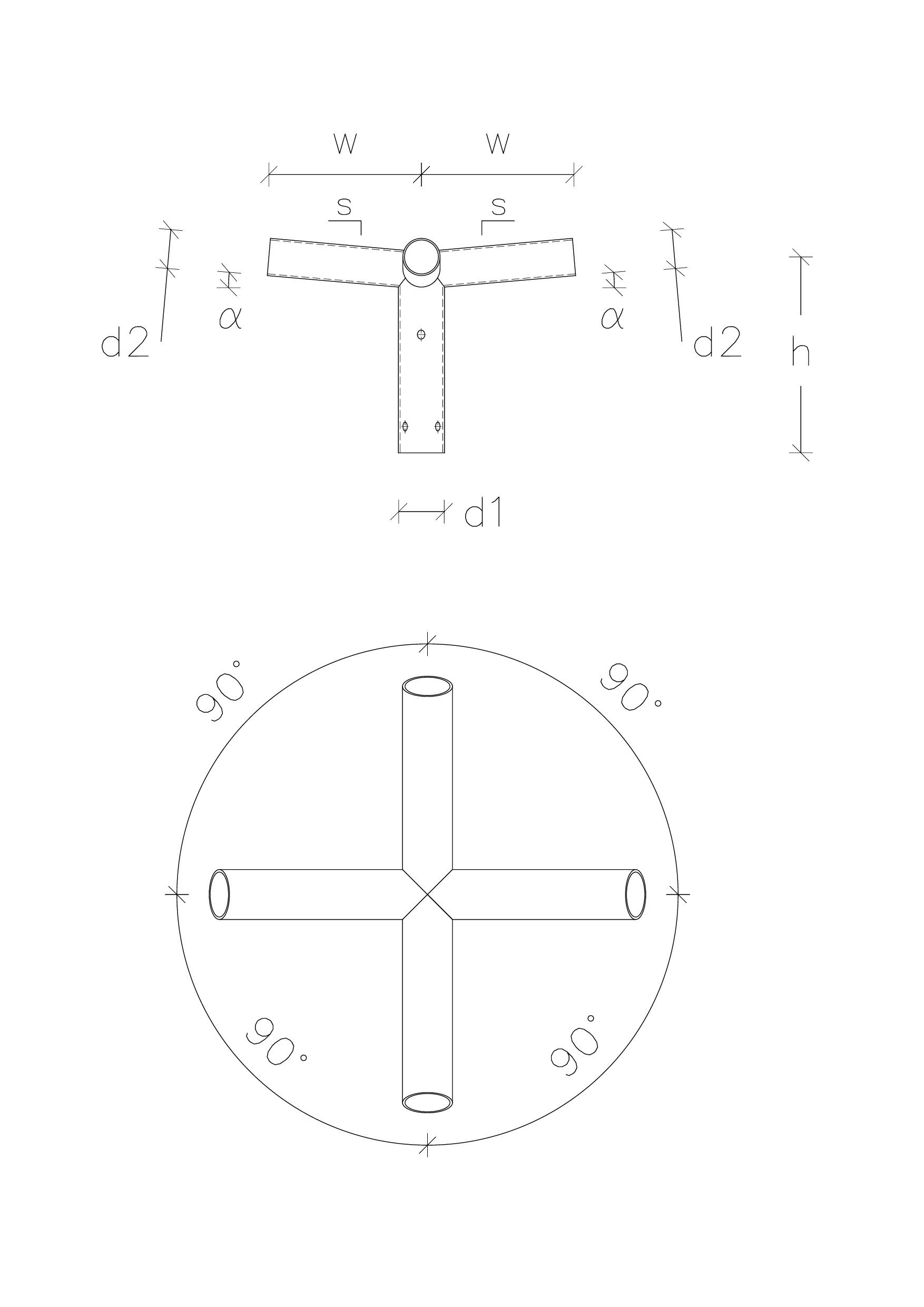

Article AA4C

Spigots applied at the top of the pole

Spigots are structural components used to support and position lights in an illumination system. These accessories connect light sources to poles or supporting structures, allowing for effective light distribution. They are commonly used in street lighting systems, parking lots, and public areas.

|

Description

|

mm

|

mm

|

mm

|

mm

|

°

|

Kg

|

|

|---|---|---|---|---|---|---|---|

| AA4C | Quadruple spigot applied at the top of the pole for poles with 60mm top. | 300 | 250 | 70 | 60 | 5 | 6 |

-

The spigots are “CE” marked through the application of an adhesive label (n° 1608 CPD P028).

The spigots are produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with current legislation (EU Regulation No. 305/2011). The label, certifying compliance with CE standards and affixed to each pole, must include: reference standard EN 40-5, manufacturer’s code, year of manufacture, product code, and the certificate number authorizing the CE marking.

-

The spigots are made of S235JR steel with characteristics in compliance with the UNI EN 10219-1-2 standard.

-

The dimensional tolerances comply with the UNI EN 1090 standard.

-

- UNI EN 1461: Hot-dip galvanized coatings on fabricated iron and steel articles.

- UNI EN 10025: Hot rolled products of structural steels.

- UNI EN 10219-1-2: Cold-formed welded structural hollow sections of non-alloy and fine grain steels.

- UNI EN 3834: Quality requirements for fusion welding of metallic materials.

- UNI EN 1090-2: Execution of steel and aluminium structures. Part 2 – Technical requirements for steel structures.

- D.M. 17/01/2018: Update of the Technical Standards for Construction.

- Circular no. 7 of 21/01/2019: Instructions for the application of D.M. 17/01/2018.

- Legislative Decree 81/2008: Consolidated Act on Health and Safety at Work.

SPIGOTS APPLIED AT THE TOP OF THE POLE model AA4C

The quadruple spigot model AA4C, manufactured by NCM, is made from a tube welded longitudinally by induction, using S235JR steel in accordance with UNI EN 10219-1-2. It has a standard inclination of 5 degrees and is designed for insertion at the top of the pole, with fixation using 6 M10 bolts. It is provided with hot-dip galvanization through immersion in a molten zinc bath, in compliance with UNI EN ISO 1461.

Dimensional characteristics of the spigots applied at the top:

| Height | : | mm | 300 |

| Projection | : | mm | 250 |

| Pole insertion diameter | : | mm | 70 |

| Lamp insertion diameter | : | mm | 60 |

| Inclination | : | ° | 5 |

Dimensional tolerances: UNI EN 1090.

Any painting, following galvanization, in a color chosen by the Project Management, is carried out using a thermosetting powder coating process. Each product will be protected with bubble wrap.