Article 9B14

Octagonal poles for MV-LV electrical lines

They are made from S355JR steel sheet (compliant with UNI EN 10025), press-bent and longitudinally welded using a procedure approved by the Italian Welding Institute, with qualified personnel.

The welds undergo quality control and testing in accordance with UNI EN 3834-2.

They have an octagonal shape with 8 sides and are composed of a single section. The connection between sections is made using the slip-on joint method.

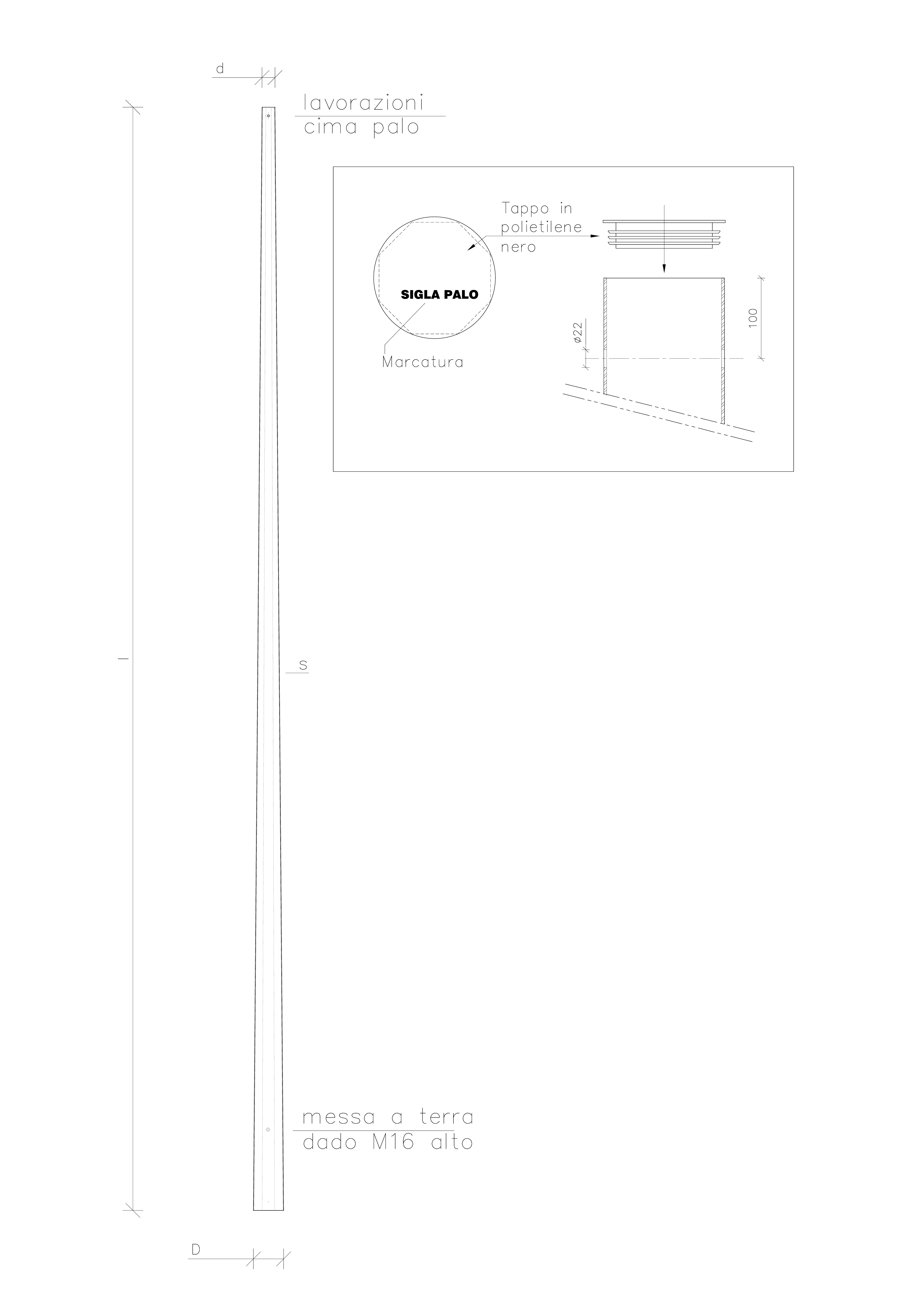

They are completed with the processes specified by Enel MAT-E&C-NC-2022-0098-GIN, Version n.0 dated 21/04/2022.

The poles are hot-dip galvanized according to UNI EN ISO 1461.

All poles are provided with a bituminous strip at the base, made of bitumen, resin, and glass fibers, applied hot with a calcium hydrate film.

An electrical shock symbol, compliant with IEC 60417 – 6042 and with a minimum size of 140 mm, is applied to the pole.

|

Serial number

|

m

|

mm

|

mm

|

Number of sections

|

mm

|

Diagram

|

Number of sides

|

daN

|

Type of steel

|

kg

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| 9B14 | 237210 | 9 | 275 | 140 | 1 | 3 | 1 | 8 | 442 | S 355 JR | 139 |

-

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard UNI EN 1090-1, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

-

The poles are made of S355 JR steel, with characteristics compliant with the UNI EN 10025 standard.

-

The tolerances comply with the technical specifications of Enel MAT-E&C-NC-2022-0098-GIN, Version n.0 dated 21/04/2022.

-

- UNI EN 1461 – Hot-dip galvanizing coatings for finished ferrous products and steel articles.

- UNI EN 10025 – Hot rolled products of structural steels.

- UNI EN 15614 – Specification and qualification of welding procedures for metallic materials. Qualification testing of welding procedures.

Part 1: Arc and gas welding of steels. - UNI EN ISO 15609 – Specification and qualification of welding procedures for metallic materials. Welding procedure specification.

Part 2: Gas welding. - UNI EN 1090-1 – Execution of steel structures and aluminium structures.

Part 1: Requirements for conformity assessment of structural components.

OCTAGONAL POLE FOR OVERHEAD LINES WELDED model 9B14

The buried octagonal pole model 9B14, produced by NCM, is manufactured from S355JR steel sheet (in compliance with UNI EN 10025), bent and longitudinally welded using a process certified by the Italian Welding Institute, with the support of qualified personnel.

The welds undergo quality control and testing in accordance with UNI EN 3834-2.

They are octagonal in shape with 8 sides and are composed of a single section.

They are completed with the processing as per Enel specification MAT-E&C-NC-2022-0098-GIN, Version n.0 of 21/04/2022.

The poles are galvanized according to UNI EN ISO 1461.

All poles are equipped with a bituminous band at the base, made of bitumen, fiberglass resins applied hot with a calcium hydrate film.

The pole bears the electrical shock symbol in accordance with IEC 60417 – 6042, with a minimum size of 140 mm.

Dimensional tolerances comply with Enel specification MAT-E&C-NC-2022-0098-GIN, Version n.0 of 21/04/2022.

Dimensional characteristics of the pole:

| Total height | : | mm | 9000 |

| Base diameter | : | mm | 275 |

| Top diameter | : | mm | 140 |

| Thickness | : | mm | 3 |

CE Marking:

The poles are CE marked by applying an adhesive label (n° 1608 CPD P028).

The pole is produced by a company certified to UNI EN ISO 9001:2015 and authorized to issue CE marking, in accordance with the current legislation (EU Regulation No. 305/2011). The label, which confirms compliance with CE standards and is affixed to each pole, must include: reference standard UNI EN 1090-1, manufacturer’s signature, year of manufacture, product code, and the CE marking authorization certificate number.

Any additional painting, after galvanization, with colors chosen by the project supervisor, is achieved through a thermosetting powder coating process. Each pole will be protected with bubble wrap.